Apollo's new oil/gas blend effectively reduces 70,000 ppm of H2S in comingled stream

Challenge

Find a cost effective hydrogen sulfide (H2S) treatment for H2S oil/gas in the Permian Basin Formation in west Texas.

Solution

Apply Apollo's new gas/oil blend to improve H2S treatment in comingled stream. Drop H2S below 3% to make gas sale viable.

Results

- Reduce H2S levels below 3% to allow for gas sales.

- Improve overall safety and integrity of company assets

- Prove Apollo's new oil/gas blend does not create fallout.

Apollo's new oil/gas blend effectively reduces 70,000 ppm of H2S in comingled stream.

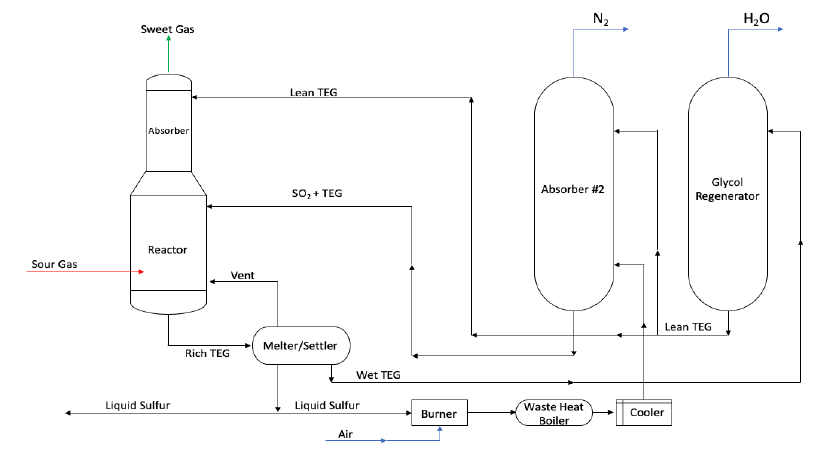

Treatment via Pipeline Injection

Reduce Hydrogen Sulfide in sour crude oil and gas.

Hydrogen Sulfide is naturally produced from the Permian Basin Formation. The levels can range from a few ppm up to 150,000 ppm hydrogen sulfide and must be reduced to below pipeline specifications, which are typically less than 10 ppm. In addition to reducing product value, hydrogen sulfide exposes producers to environmental and safety risk and increases the chance of corrosion.

Producer in West Texas currently deals with high H2S. Apollo has been tasked with treating the Hydrogen Sulfide using their new gas/oil product which will reduce the H2S thus allowing for gas spec of under 3% H2S. Apollo then utilizes its Apcotane™ product to treat the oil stream after separation to zero ppm of H2S allowing for pipeline spec. This will also help to increase the price per barrel realized while eliminating scale that has been an issue for the producer.

Apply Apcotane Ultra Lite to treat oil, increase profits.

The operator tasked Apollo with improving the treating efficiency of hydrogen sulfide in comingled stream of oil and gas. The flow that Apollo's chemistry interacted with thru the pipeline structure was roughly 10,000 bbl/oil a day and 10 MMCF of gas per day after a water knockout. The stream generally averages around 10% of H2S and 6% CO2. Apollo is able to inject their new oil/gas blend into the pipeline stream via one injection point. In about 100 foot of pipe Apollo has been able to reduce H2S in gas phase to 3% and CO2 to 2%. Apollo has been able to run the stream successfully for 7 months Producer has been able to increase production due to the ability to economically treat. A. Alleviating 50,000 lbs/S off of their sulfur plant and an additional 30,000 lbs of CO2. Apollo has also been able to deal with the spikes of the wells which can exceed 150,000 ppm of H2S and continue to make it sour pipeline spec.

This is a ground-breaking chemistry for the oil and gas world. Showing Apollo's new blend is able to economically treat high H2S and allow both streams to be sold. This will allow capped wells to be able to come online, now that there is an economical treatment for the gas stream.