Occidental Petroleum INC

Produced water and Hydrocarbons containing soluble and vapor phase H2S (Hydrogen Sulfide)

Intro

Apollo petroleum laboratories is a petroleum-based research laboratory of patented and proprietary products that are engineered for the dissolution of soluble and vapor phase H2S. This molecule is commonly associated with production oil, natural Gas, and produced water.

The Apollo chemical product line is a result of 25 years of research at major universities along with in-house research studies directed specifically on our client’s production challenges.

goal

To develop new chemical products and methods to mitigate H2S, corrosion, scaling, improve employee safety, protection of corporate assets, and provide greater efficiencies in production and lower overall operating production costs.

product line

Apcotane™

is highly engineered for the mitigation of H2S, both soluble and vapor phase in production crude. Apcotane has no upper limit of H2S in production oil of an API of 6 (oil asphaltene) to 50 API. Apcotane treats H2S efficiently in concentrations from 1000 ppm to 400,000 ppm. Typical dosing rate is .6 mg/l to 1.2 mg/l. This product based on molarity is one mole of Apcotane will mitigate 40 moles of H2S. Compared to Triazene at one to three moles of Triazene per mole of H2s. Apcotane is at least 40 times the efficiency. Apcotane provides a non-reversible reaction where the production oil has been treated with Apcotane and heated to 1800 degrees F, with no return of any soluble or vapor phase H2s. This process treatment has no fallout of salts, carbonates, chlorides.

Vap-X™ Oil Blend

is a highly engineered chemical with a high vapor pressure for the mitigation of H2s in oil with a higher water cut. The water cut will not dilute the Vap-X chemical therefore maintaining the reactive strength and efficiencies of the chemical while treating the H2s to zero ppm with no fallout or scaling or corrosion to the mechanical assets. Typical dosing rate is .6 mg/l to 1.5 mg/l to mitigate 100,000 ppm of H2s to zero.

Vap-X™ 3 Phase

has been formulated to greatly reduce H2S and CO2 in an oil, water, and gas system. It effectively reduces all three streams by 50-70% of its H2S and CO2. The product adjusts the pH of the water from the acidic phase to a neutral pH once the reaction is complete. Vap-X™ 3 Phase is engineered with a higher RVP allowing the treatment of the gas phase via gas partitioning. The chemical is applied utilizing a static mixer via a commingled stream (oil, gas, and water) allowing for turbulent mixing between the three phases. A critical aspect of the treatment is the mixing energy to make sure all the molecules have contact with the solution. With very minimal capital expenditure this product will show how it can impact a field. Bring shut-in production back online with ability to treat previously thought to be uneconomical wells to produce. Vap-X™ 3 Phase is best utilized in high H2S concentrations with consistent liquid flow. The dosing rate is based on volume of liquid flow rate and water volume where pH is controlled to help mitigate fallout from occurring. Vap-X™ 3 Phase also has a proprietary chemical additive that acts as a corrosion inhibitor.

Vap-X™ Natural Gas Blend

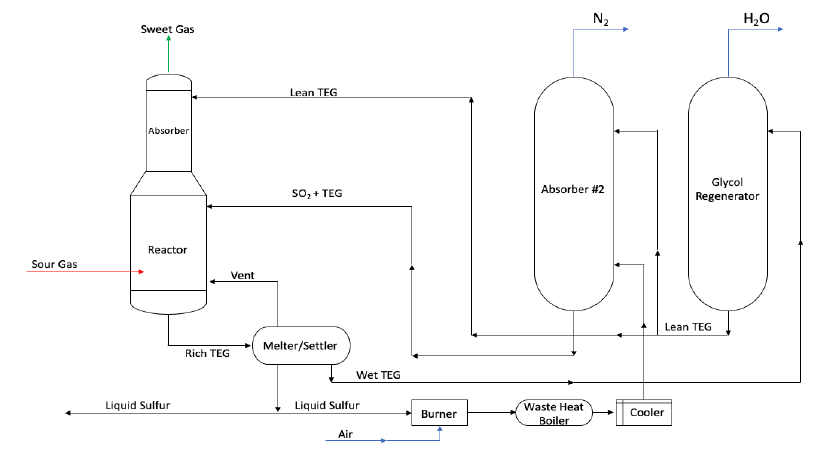

is a highly engineered for the mitigation of H2S in produced natural gas reducing 100,000 ppm of H2S to 40,000 ppm CO2 (carbon dioxide) is reduced from 80,000 ppm to 200 ppm This reduction of H2S and CO2 reduces the sulfur loading on the amines scrubber allowing greater production and allowing an increase in oil production. This chemical process will allow for shut-in wells to be open allowing for production increasing from nonproducing assets. This process is efficient and cost effective adding to corporate profits without Capital Expense outlay for future development of production wells, instead utilizing existing field assets.

Mer-X™

Mitigation of mercaptans sulfur compounds 90 to 98 % effective. Currently this process has been established in the lab. Field testing is under way.

Sul-X™

Mitigation of total sulfur 50 to 60 % effective. Currently this process is being tested in lab for further studies.

Apcotane™ H2O

is commonly used for H2S in water where the water is disposed of downhole thus mitigating the H2S reducing corrosion, scaling, salt fall-out, carbonates that blind or reduce pipe diameters thereby decreasing production. Apollo laboratories can also develop a process to clean the production water for re-use to fracking specs or many other uses.

Produced Water Challenges are treated slightly different for H2S, salts, carbonates and other composition contaminates. Depending on the concentrations of contaminates and the purposed disposal or re-use of the water dictate’s the process treatment.

Apollo laboratories works very close with its clients to resolve the oil industry challenges and provide new cutting-edge technologies to its clients. Helping resolve challenges very efficiently, cost-effective, all while improving site safety therefore adding to corporate bottom-line.

Apollo laboratories proposal to Occidental is a cost free to send a 5-gallon sample to Apollo labs with an outline of challenges and specs they would like to achieve. Apollo will run the sample in our lab to find the best cost-effective solution that we can then produce. Analytical results showing the final composition and reduction of contaminates will be produced. Once we have the process and analytical to present to occidental, we can then figure out the next steps moving forward.

This approach has no obligation on occidentals’ part. Apollo is very committed on validating that our chemicals and solutions perform exactly how they are explained. We like to provide our clients the best solutions that fit in the corporate budget.

The above product line has been deployed and on the market for 5 years with no disruption to production in pipelines, oil producers, natural gas producers, refineries, transportation. Our products meet federal transportation, natural gas commission, and petroleum commission guidelines. All research and treatments are confidential to its respective client.

Other Areas of Ongoing Research

- Corrosion of Organic Acids

- Scaling of Production Fallout

- H2S of Natural Gas

- Produced Water Fallout, Suspended Solids Due to H2S

- Total Sulfure Reduction

- Production Efficiencies Associated with RVP

- Aviation Fuels Efficiencies, Combustion Gas Emissions

- Motor Vehicle Fuels, Combustion Gas Emissions

- Produced Water Contaminates and Re-Purposed Water

- Production Natural Gas Emissions

Apollo currently has clients around the world from oil producers, refineries, pipelines, shipping, USA oil reserve, USA government aviation fuels, USA government motor fuels both private and Military, Middle east oil producers, USA oil and gas producers.